Categories

Brands

300T Series CNC Lathe System

B Series 7-Inch CNC Lathe System (Horizontal)

1. Supports IoT interface for real-time acquisition of machining data, making management more convenient. </br> 2. Supports polar coordinate interpolation: by editing instructions in Cartesian coordinates, it can realize interpolation contour control between linear and rotary axes. Application scenarios: cam machining, outer diameter milling of workpieces, irregular workpiece milling. </br> 3. Supports polygon cutting (flying cutter): Polygon cutting technology utilizes multi-spindle configuration to achieve fast polygon turning, greatly improving machining efficiency.

B Series 8-Inch CNC Lathe System (Horizontal)

1. Supports IoT interface for real-time acquisition of machining data, making management more convenient. 2. Supports polar coordinate interpolation: by editing instructions in Cartesian coordinates, it can realize interpolation contour control between linear and rotary axes. Application scenarios: cam machining, outer diameter milling of workpieces, irregular workpiece milling. 3. Supports polygon cutting (flying cutter): Polygon cutting technology utilizes multi-spindle configuration to achieve fast polygon turning, greatly improving machining efficiency.

B Series 10.4-Inch CNC Lathe System (Horizontal)

1. Supports IoT interface for real-time acquisition of machining data, making management more convenient. 2. Supports polar coordinate interpolation: by editing instructions in Cartesian coordinates, it can realize interpolation contour control between linear and rotary axes. Application scenarios: cam machining, outer diameter milling of workpieces, irregular workpiece milling. 3. Supports polygon cutting (flying cutter): Polygon cutting technology utilizes multi-spindle configuration to achieve fast polygon turning, greatly improving machining efficiency.

B Series 15-Inch CNC Lathe System (Vertical) 300TA4-V

1. Supports IoT interface for real-time acquisition of machining data, making management more convenient. 2. Supports polar coordinate interpolation: by editing instructions in Cartesian coordinates, it can realize interpolation contour control between linear and rotary axes. Application scenarios: cam machining, outer diameter milling of workpieces, irregular workpiece milling. 3. Supports polygon cutting (flying cutter): Polygon cutting technology utilizes multi-spindle configuration to achieve fast polygon turning, greatly improving machining efficiency.

400T Series CNC Lathe System

B Series 8-Inch CNC Lathe System (Horizontal)

This series of lathe controllers is equipped with high-speed and high-precision modes, integrated lathe and robotic arm control, safety zone functionality, and automatic thermal compensation, ensuring high product quality during machining.

B Series 10.4-Inch CNC Lathe System (Horizontal)

This series of lathe controllers is equipped with high-speed and high-precision modes, integrated lathe and robotic arm control, safety zone functionality, and automatic thermal compensation, ensuring high product quality during machining.

B Series 15-Inch CNC Lathe System (Vertical)

This series of lathe controllers is equipped with high-speed and high-precision modes, integrated lathe and robotic arm control, safety zone functionality, and automatic thermal compensation, ensuring high product quality during machining.

B Series 8-Inch CNC Lathe System (Horizontal)

This series of lathe controllers is equipped with high-speed and high-precision modes, integrated lathe and robotic arm control, safety zone functionality, and automatic thermal compensation, ensuring high product quality during machining.

600T Series CNC Lathe System

B Series 8-Inch CNC Lathe System (Horizontal)

1. Y-axis Interpolation for Turn-Mill Compound: Adaptable to processing a wider variety of products and machine models. 2. Standard Dual-Spindle Configuration: Improves machining efficiency and supports multi-process machining. 3. Lathe + Robot Arm: Enables automatic loading and unloading, reducing manual labor.

B Series 10.4-Inch CNC Lathe System (Horizontal)

1. Y-axis Interpolation for Turn-Mill Compound: Adaptable to processing a wider variety of products and machine models. 2. Standard Dual-Spindle Configuration: Improves machining efficiency and supports multi-process machining. 3. Lathe + Robot Arm: Enables automatic loading and unloading, reducing manual labor.

B Series 15-Inch CNC Lathe System (Vertical)

1. Y-axis Interpolation for Turn-Mill Compound: Adaptable to processing a wider variety of products and machine models. 2. Standard Dual-Spindle Configuration: Improves machining efficiency and supports multi-process machining. 3. Lathe + Robot Arm: Enables automatic loading and unloading, reducing manual labor.

800T Series CNC Lathe System

B Series 8-Inch CNC Lathe System (Horizontal)

1. Five-axis simultaneous turning and milling compound: Control with five degrees of freedom, suitable for machining parts with various shapes and curves. 2. Double turning and milling compound: Multi-process machining of complex workpieces. 3. Double turning + robot: Automatic loading and unloading, improving production efficiency.

B Series 10.4-Inch CNC Lathe System (Horizontal)

1. Five-axis simultaneous turning and milling compound: Control with five degrees of freedom, suitable for machining parts with various shapes and curves. 2. Double turning and milling compound: Multi-process machining of complex workpieces. 3. Double turning + robot: Automatic loading and unloading, improving production efficiency.

B Series 15-Inch CNC Lathe System (Vertical)

1. Five-axis simultaneous turning and milling compound: Control with five degrees of freedom, suitable for machining parts with various shapes and curves. 2. Double turning and milling compound: Multi-process machining of complex workpieces. 3. Double turning + robot: Automatic loading and unloading, improving production efficiency.

400M Series CNC Milling System

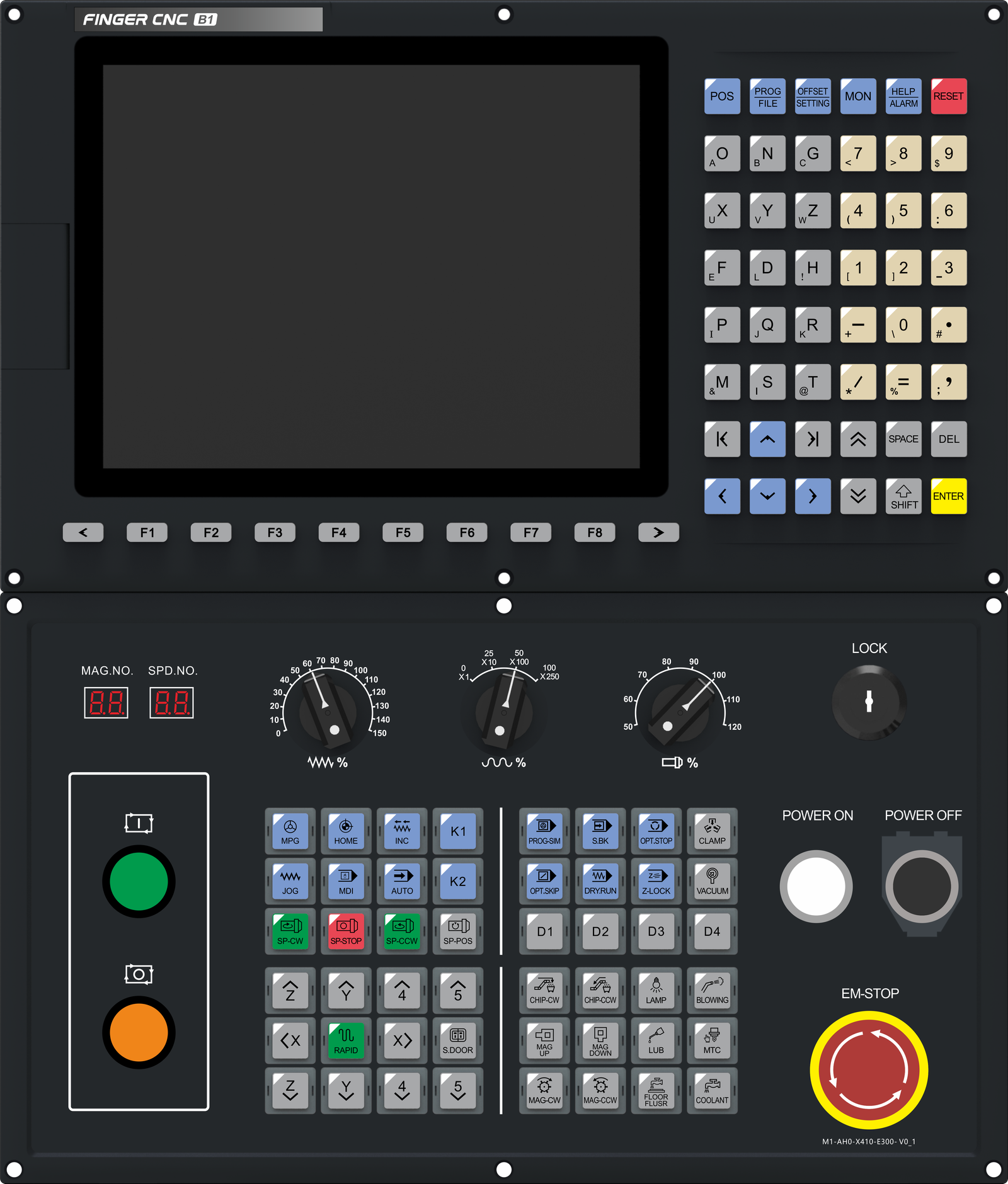

B Series 7-Inch CNC Milling System (Horizontal)

1. High-definition LCD display. 2. Supports 3 or 4-axis CNC milling control (XYZ or XYZ + 4th axis). 3. Supports conventional graphical conversational programming for easy operation. 4. Comprehensive machining modes: not only supports standard milling operations, but also hole and thread machining including drilling, reaming, tapping, countersinking, boring, and milling various hole sizes, making it suitable for diverse workpieces. 5. EtherCAT or MECHATROLINK-III bus control for enhanced real-time performance and easier maintenance. 6. Optional IoT support for real-time access to machining data, enabling more efficient management.

B Series 8-Inch CNC Milling System (Horizontal)

1. High-definition LCD display. 2. Supports 3 or 4-axis CNC milling control (XYZ or XYZ + 4th axis). 3. Supports conventional graphical conversational programming for easy operation. 4. Comprehensive machining modes: not only supports standard milling operations, but also hole and thread machining including drilling, reaming, tapping, countersinking, boring, and milling various hole sizes, making it suitable for diverse workpieces. 5. EtherCAT or MECHATROLINK-III bus control for enhanced real-time performance and easier maintenance. 6. Optional IoT support for real-time access to machining data, enabling more efficient management.

B Series 10.4-Inch CNC Milling System (Horizontal)

1. High-definition LCD display. 2. Supports 3 or 4-axis CNC milling control (XYZ or XYZ + 4th axis). 3. Supports conventional graphical conversational programming for easy operation. 4. Comprehensive machining modes: not only supports standard milling operations, but also hole and thread machining including drilling, reaming, tapping, countersinking, boring, and milling various hole sizes, making it suitable for diverse workpieces. 5. EtherCAT or MECHATROLINK-III bus control for enhanced real-time performance and easier maintenance. 6. Optional IoT support for real-time access to machining data, enabling more efficient management.

600M Series CNC Milling System

B Series 8-Inch CNC Milling System (Horizontal)

1. High-definition LCD display 2. Supports 3, 4, and 5-axis CNC milling machine control (XYZ or XYZ + 4th axis or XYZ + 4th and 5th axes) 3. Expandable up to 2 channels and 14 axes 4. High-speed, high-precision algorithms 5. Gantry axis control with gantry axis error protection, error correction, and dual motor backlash elimination 6. Powerful special functions: Includes angle following function that allows the third axis to automatically track 2D curves, providing solutions for tool path curve cutting industries; automatic taper compensation resolves taper issues caused by spindle non-parallelism and worktable XZ non-parallelism, making usage easier and compensation more accurate 7. EtherCAT or MECHATROLINK-III bus control for higher real-time performance and easier maintenance 8. Optional IoT support for real-time acquisition of machining data and more convenient management

Recently Viewed Items

No recently viewed items.

PLC Migration and Upgrade Services

Upgrade your programmable logic controllers (PLCs) to state-of-the-art equipment through our comprehensive solutions. Our services ensure seamless migration, minimal downtime, and enhanced performance for your automation systems.

Discover our services >

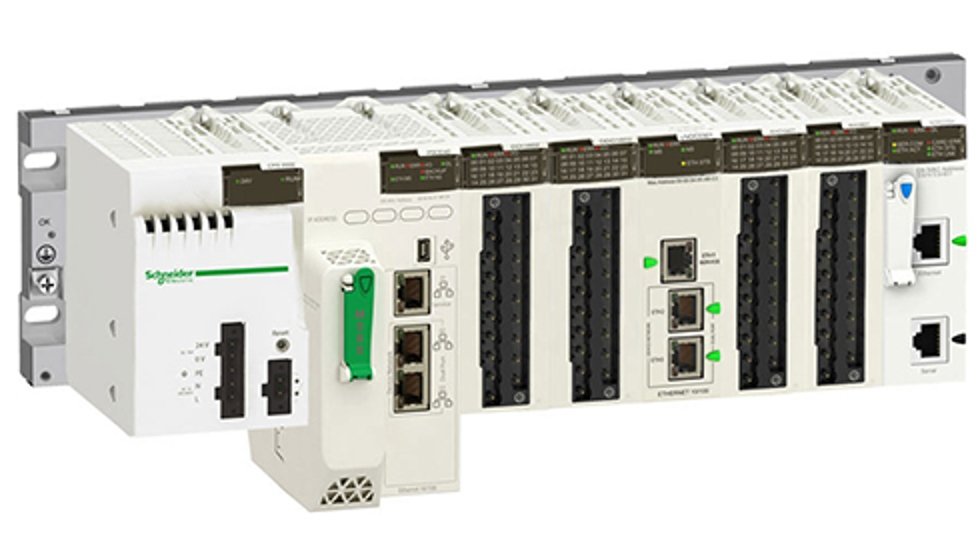

Discover Modicon M580 PAC

The Ethernet-based Modicon M580 PAC controller offers advanced connectivity capabilities to help you react more quickly to information demands, within a secure environment. It supports high-speed data processing and robust cybersecurity features.

Discover now >

Process Automation Learning Services

Explore our digital and in-person courses, specially designed to ensure the technical skills of your automation workforce are future-ready. Or request custom learning solutions tailored to address your unique training needs, including hands-on workshops and certification programs.

Discover now >